Discover industrial robotics

Our products are created to meet the most modern needs of industry. Versatile and reliable, they are suitable for a variety of uses: sorting, assembly, glue coating, inspection, loading and unloading, packaging, deburring, and more.

High precision movement to positions specified with coordinate values. High precision movement at specified positions with coordinate values. Robot machining and assembly errors, zero-point errors of the joint angle sensors, and arm deflection are minimised by factory settings calibrated to the virtual model.

Limits damage of tool and workpiece by signaling the robot to halt upon collision. The function works independent of external sensors, and its sensitivity can be adjusted to accommodate applications requiring force application.

Conveyor calibration and grab calibration to achieve high grasping accuracy. The system supports Cognex and McMaster camera or any general camera, which supports the TCP/IP protocol.

Enables configuration of up to four external axes; linear or rotational independent of robot axes. Each axis can be set as independent or interpolated, in modality independent, synchronous or asynchronous axis can be set, and switched by the program.

Simple graphic interface for advanced palletizing consists of single-layer layout styles including: row, column, group and pinwheel, in a customizable sequence. Singularities and reachabilities can be checked via virtual simulation.

Provides device configuration interface and subroutine for varied brands of welding devices. It also supports different weaving types such as triangle, sine, figure 8, and circle. GUI provides a clear guide to program interface.

SCARA Robots

Efort Robotics SCARA robots cover payloads between 3 and 10 kg with extension: 400 ~ 800 mm and repetition accuracy: ±0.01 ~ ±0.02 mm on axes J1+J2, ±0.01 mm on axis J3 and ±0.01° on axis J4.

Highlights

High reliability, high processing speed, high protection.

Applications

Handling, tending, assembly.

General industry, mechanical field, moulding, plastics.

Load capacity from 3 to 10 kilograms

Radius between 400 and 800 millimetres

0.02mm

Repeatability between ±0.01 and ±0.02 millimetres

Small Robots

Efort Robotics small robots cover payloads between 8 and 12 kg with arm extension: 593 ~ 2025 mm and repeat accuracy: ±0.02 ~ ±0.03 mm.

Highlights

Efficient, accurate, user-friendly, stable, compact.

Applications

Sorting, assembly, glue coating, inspection, loading and unloading, packing, deburring and more.

Metal processing, electronics, Food and beverage packaging, Pharmaceuticals, Logistics warehousing.

Load capacity from 8 to 12 kilograms

Radius between 593 and 2025 millimetres

0.03mm

Repeatability between ±0.02 and ±0.03 millimetres

Arc Welding

Efort Robotics arc welding robots cover loads between 10 and 15 kg, with the radius: 1400 ~ 2000 mm and repeatability: ±0.03 mm.

Highlights

High protection, high throughput, high reliability.

Applications

Handling, assembly, machine tending, polishing, coating, deburring and other applications.

Automotive, Sanitaryware, Photovoltaics, Electronics, Moulding.

Load capacity from 10 to 15 kilograms

Radius between 1400 and 2000 millimetres

0.03mm

Repeatability of ±0.03 millimetres

Medium Robots

Efort Robotics medium robots cover loads between 10 and 35 kg, with the radius: 1143 ~ 2295 mm and repeatability: ±0.03 ~ ±0.05 mm.

Highlights

High protection, high throughput, high reliability.

Applications

Handling, assembly, machine tending, polishing, coating, deburring and other applications.

Automotive, Sanitaryware, Photovoltaics, Electronics, Moulding.

Load capacity from 10 to 35 kilograms

Radius between 1143 and 2295 millimetres

0.05mm

Repeatability between ±0.03 and ±0.05 millimetres

Palletizers

Efort Robotics palletising robots cover loads between 130 and 180 kg, with the radius: 2800 ~ 3200 mm and repeatability: ±0.1 mm.

Highlights

High overload, high throughput, high beat, high reliability.

Applications

Metal processing, loading and unloading, grinding, welding, handling and other applications.

Automotive, Sanitaryware, Photovoltaics, Electronics, Moulding.

Load capacity from 130 to 180 kilograms

Arm stretch between 2800 ~ 3200 mm.

0.1mm

Repeatability of ±0.1 millimetres

High Loads

Efort Robotics high load and palletising robots cover loads between 50 and 210 kg, with the radius: 2146 ~ 3160 mm and repeatability: ±0.06 ~ ±0.1 mm.

Highlights

High overload, high throughput, high beat, high reliability.

Applications

Metal processing, loading and unloading, grinding, welding, handling and other applications.

Automotive, Sanitaryware, Photovoltaics, Electronics, Moulding.

Load capacity from 50 to 210 kilograms

Arm stretch between 2146 ~ 3160 mm.

0.1mm

Repeatability between ±0.06 and ±0.1 millimetres

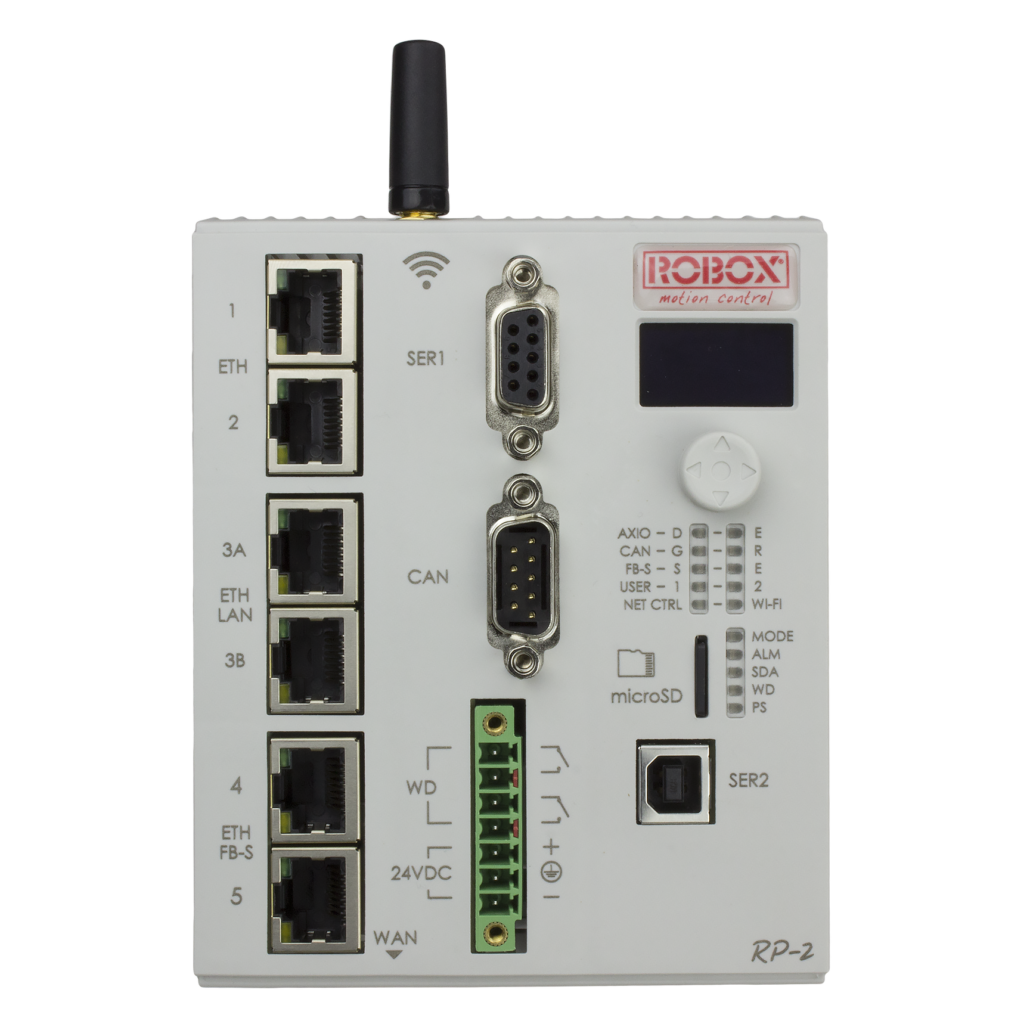

RP-2 (Profinet slave) | AS1018.012

Motion controller – equipped with CPU ARM Cortex A9 Dual Core (800MHz) able to control up to 32 interpolated axes, driven through EtherCAT fieldbus.

Furthermore it is also equipped with Profinet slave interface.

Highlights

- Microprocessor ARM Cortex A9 Dual Core (800MHz)

- Number of controlled axes: up to 32 interpolated axes, driven through Ethercat fieldbus

- Memory: Micro SD flash memory, 1 GB DRAM, 512 Kbyte retentive memory ram for parameters and alarm history storage

- Communication:

- n. 2 10/100 Mbits/s Ethernet channels dedicated to Master fieldbus (EtherCAT CoE, SoE, EoE) for axes control and/or remote I/O

- n. 2 10/100 Mbits/s Ethernet channels dedicated to Slave fieldbus ProfiNET slave

- n. 2 10/100 Mbits/s Ethernet channels with internal switch for general purposes (TCP/IP, UDP, TFTP, Modbus/TCP, Ethernet/IP, Robox BCC/31/TCP, OPC-UA)

- n. 1 Wi-Fi channel

- n. 1 10/100 Mbits/s Ethernet channel with WAN functionality

- n. 1 Canbus channel (Master DS301, DS401, DS402, protocols for axes control and/or remote I/O, Device Net, Robox Cnet)

- n. 1 USB-B-UART serial channel for general purposes (Robox BCC/31, DF1)

- n. 1 RS232 serial channel for general purposes (Robox BCC/31, DF1)

- Master bus Axioline for communication with Axioline peripherals

Diagnostic web server - O.P.C. Server, ActiveX, .Net Library, rLibQt, rLibJava and rLibC++ available for communication in Windows environment

- Expansion boards: see remote I/Os (the bus coupler AXL-F-BK-C is not necessary), double contact Intrinsic safety watch dog relay, 128×64 OLED Display for diagnostic and monitoring of the CPU status, equipped with a joystick

- Remote service

- Real-time clock calendar

- 24 VDC Power Supply

- External measures: mm 100x123x96; 0.5Kg

- Vertical or horizontal mounting in 35mm DIN guide in accordance with EN60715 standard

- Programmable through RDE3 Development Environment